Pizza-Porta 2.0 - manufacturing updates

The initial product design for the Pizza-Porta was actually done through many iterations in cardboard at my dining room table. I tried and tried to get a wedge with an opening to cook great pizza, but it just didn’t work. After a great deal of input from metal fabrication experts, we developed the original origami design with a door. We then watched user feedback and learned a lot from cooking thousands of pizzas. One thing that jumped out was the overkill in the original design. When in doubt we made it heavier - and then we welded it too! We also had a multi-point hinge pin that would withstand thousands and thousands of door opening drops. The original version was so heavy-duty it was better suited for a commercial cooking setting than cooking pizza on the weekends. When we began discussing a new design, it could take advantage of new, more precise manufacturing equipment. Here is a recap of the changes that make the new model a step forward.

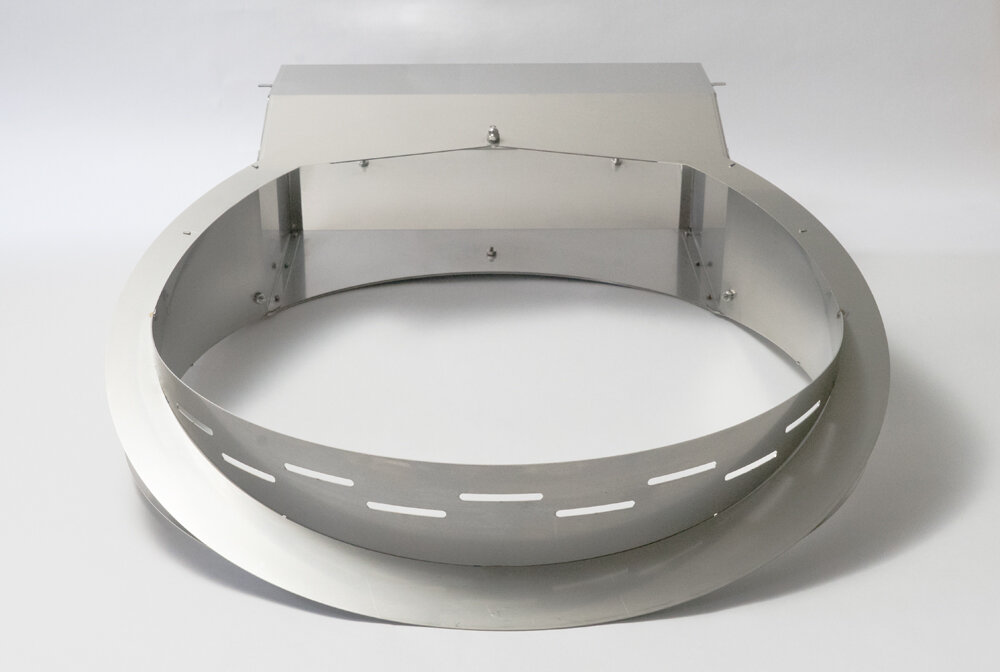

1) Smooth sides. The most obvious difference is the design of the sides of the unit. This change required a whole new thought process. The curved sides better match the shape of the BGE and also allow a simplified manufacturing process. It required pulling out some rolling equipment, but it was a simple process.

2) Reflective ring. The ring acts as a shiny heat deflector, focusing radiant heat on the crust all the way around the pizza while the interior slots disturb the vertical airflow for better heat distribution.

3) Removable door box. We listened to user feedback and made a design that would conveniently disassemble for shipping as well as storage.

4) Double Rack Compatible. Taking advantage of the rear reflector height and the side bolts, we designed a set of optional brackets that hold 2 - 14” pizza stones in the correct position. (The previous RCL free-standing double rack will also work, but the new rack is at a fixed height regardless of internal setup.)

5) Gasket rings. By creating a flat surface for the gasket, the unit has a positive seal against the top and bottom gaskets.

6) Simplified attachment. By taking advantage of a new, more precise laser, we are able to create tabs and slots with enough precision to attach the parts without welding. This simplifies assembly and allows some thermal flexibility when the unit expands.

7) Single point dome retention. A simple, single acorn nut retains the unit in the grill when opening and closing the door.

8) Material - There are some other pizza oven attachments for kamado grills. These units are less expensive because they chose different materials. We tested powder-coated aluminum (the finish flakes off and the material does not handle high temperatures), and painted steel (one cook and even high-temperature paint fails leaving the steel exposed to rust). We stuck with 300 series stainless (not even lower cost, magnetic 200 series which rusts at these temperature cycles) so that the product would stand up to high pizza temperatures and resist rust for years of pizza making.

9) US made. We chose to continue to manufacture the Pizza-Porta here in the US, rather than bid it out to a factory overseas. We have recently move manufacturing to a partner in northern NY that has been making metal goods for 115 years at the same location.

All of these improvements were made thanks to discussions with customers and our dealers. Thank you for all of the feedback along the way.